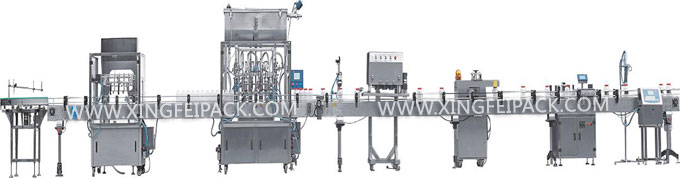

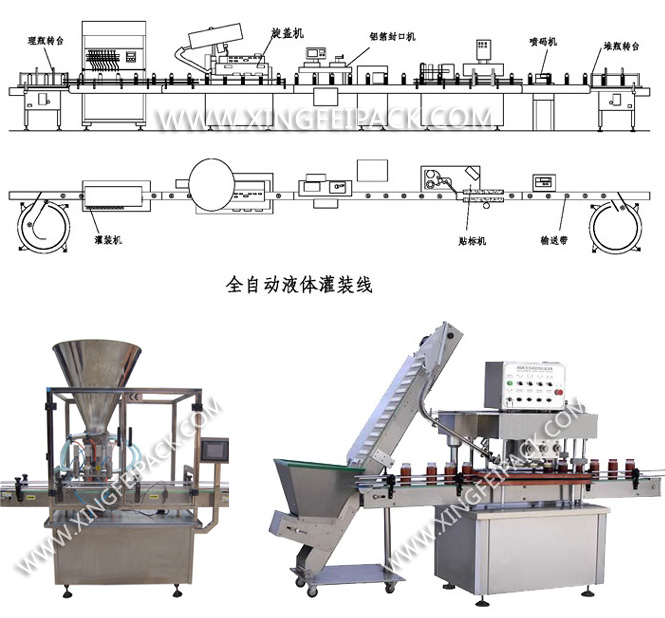

XFY Linear Liquid Filling and Capping Machine

I. Application:

This machine is mainly used for filling, lidding, capping the 30-500ml bottles. The machine is combined the process of filling and capping with the function of advanced design, compact structure and easy bottles change.

II. Technical Parameter:

|

Output

|

60-80B/M |

|

Bottle specification |

30-500ml glass or plastic bottle |

|

Sealing rate |

≥99% |

|

Sealing way |

Capping, crimpping or spiral twisting |

|

Power supply |

380V 50Hz three-phase |

|

Power |

2Kw |

|

Dimension(mm) |

2900×1300×1650 (including bottle feeding machine) |

XF-TB Self-adhesive Labeling Machine

I. Application:

The machine is applicable for labeling Columned or square plastic bottles, glass bottles or similar containers in food, light, pharmacy, and chemical industries。

II. Character:

1. the machine has the processes of feeding bottles and labels separating, labeling and legible batch numbers marking. The machine is driven by large drive step motor and equipped with advanced electromechanical integrating technique such as Japan OMRON optoelectronic control device and power source protection system. It has the characteristics of start buffering, high flexibility, stable speed, constant working voltage and anti-disturbance to ensure the labeling operation is precise, stable, reliable and high efficient. It is the option to use the machine either as single unit or for production line.

III. Technical Parameter:

|

Labeling Range:

|

Φ20~100mm |

|

Working Capacity |

80~200B/MIN |

|

The inside diameter of label-roll |

Φ76mm |

|

The outside diameter of label-roll |

Φ300mm |

|

The length of label |

20~200mm |

|

The height of label |

20~100mm |

|

Power |

200V/50HZ 250W |

|

Dimension |

1820×1100×1500mm |

|

Weight: |

200Kg |

XF-LF Electromagnetic Induction Aluminum Foil Sealing Machine

I. Brief instruction:

The electromagnetic induction aluminum foils sealing machine works based on the electromagnetic induction principle. It produces swirled and instant heat on the surface of the foil so that the foil may stick to the bottle mouth and reaches the purpose of sealing bottles with sealed caps.

II. Character:

1.The sealing quality won’t be affected even if there is a small amount residual material left on the bottle mouth, the machine avoids overflowing, moisture-proof, anti-mildew, extending the preservation time of the product in bottle, meets the GMP requirement.

2.This machine has the of self checking function; it can protect itself when the flowing pressure, temperature are over-standard.

3.Cooling system adopts double water-cooling cycle, to be cooling sensors and power module respectively.

4.The power can be adjusted, the machine has the advantage of fast sealing, strong sealing good separating quality of the aluminum foil and cardboard. The machine can be used in the assembly line. This machine can be matched with bottle-supply machine, bottle-eliminate machine, it is easy to install

III. Application:

It is applied to pharmacy, veterinary drugs, insecticides, brewing, flavor, lubricants, and cosmetic industries and so on. At the same time the machine has the function of sealing, anti-counterfeits and anti-theft.

IV. Technical Parameter:

|

Powder supply

|

220V/50Hz |

|

Power |

2kw |

|

Hole diameter |

ф20-100mm |

|

Bottle height |

30-260mm,Special one can be customized |

|

Speed |

60--120pcs/min |

|

Weight |

180kg |

|

Dimension |

1800×500×1300mm |